We are a professional beer and beverage bottling machine manufacturer with more than 18 years’ experience. Our company was established in 2003.

We have a strong technology technology resources development and production team, which has two lead engineers with twenty years of experience, two senior electrical engineers, five overseas installation engineers over 30 years, about sixty assembly workers with 5-20 practical production experience.

Our production technology of beer bottling machines adopts German Technology and combines it with the characteristics of the beer production industry. We are committed to creating the operation reliability and improved rinsing&filling&capping function. We can provide various capacity beer& beverage filling machines, and we are especially famous for small-scale beer filling machines. In our workshop, over 80% of machines are produced for beer and carbonated drink filling machines.

According to industry statistics, our factory is the supplier who used the beer filling valves most in local. The China famous top brand of SNOW beer and QINGDAO beer are our cooperated clients. And we also have clients in the US, Canada, South America, Europe, the Middle East, Southeast Asia, and Africa. The friends in the whole world are welcomed to visit our factory, we are looking forward to having a long term and win-win cooperation as well. Our products have passed European CE Certification and ISO9001&2000 Certification. Our Corporate Mission is “Honesty, Excellence, Quality, Service”.

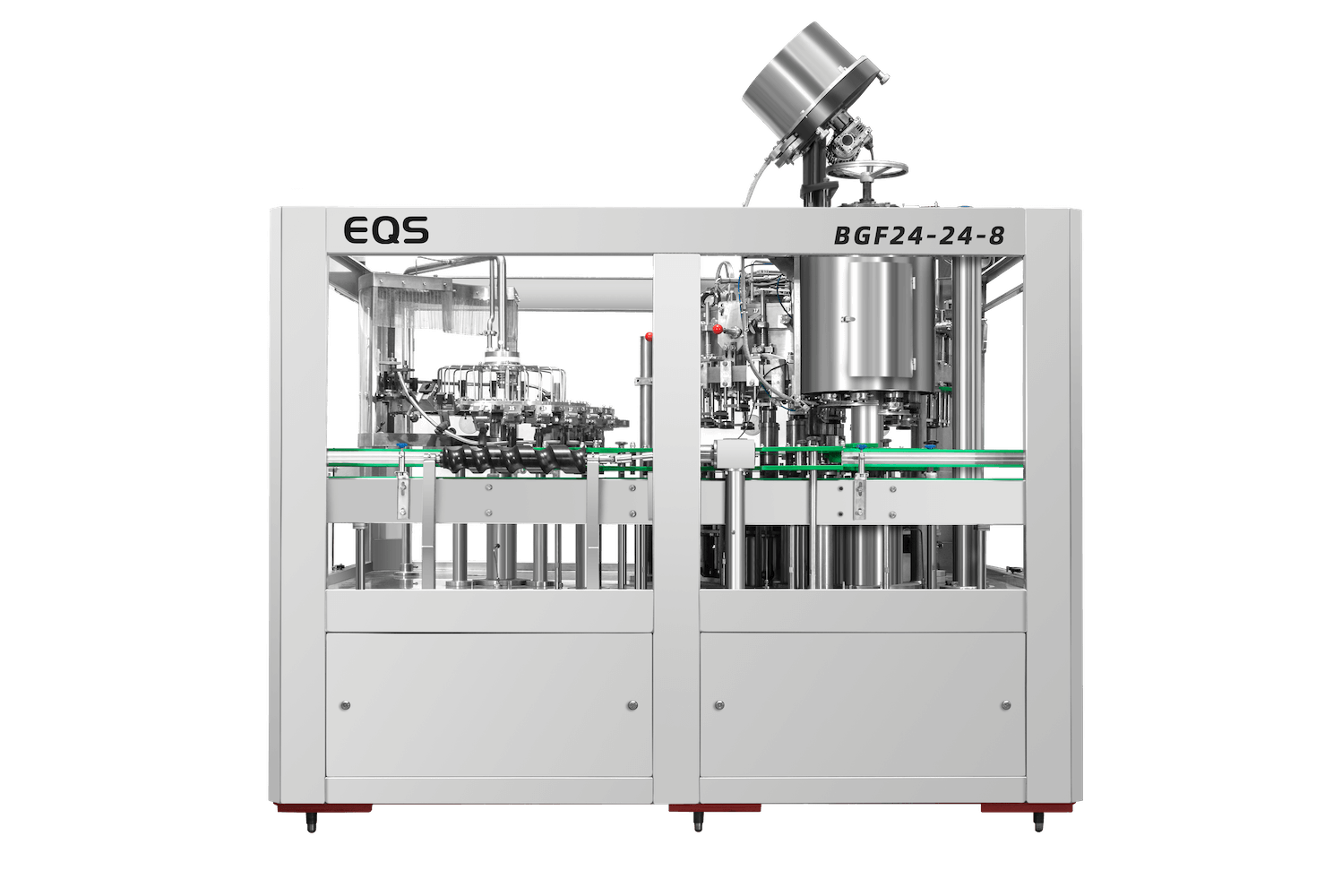

Our beer filling machine adopts German technology and the latest industrial production technology. It adopts the vacuum filing method. We can customize with twice vacuum to reduce oxygen content according to the client’s actual request.

The equipment is equipped with famous abroad brand electrical components( such as Siemens and Schneider,…), with a complete set of CIP clean connection ports for keeping a clean filling environment, and with a centralized lubrication system for guaranteeing long time work performance. And it’s controlled by PLC, no bottles stop filling. Automatic frequency step-less speed adjustment, easy to operate on the touch screen. We can control the liquid level within 2mm for batch production since there is an electric probe to assure the precise liquid level.

The main structure consists of a bottle inlet screw, washing part, filling part, capping part, and bubble device. The beer filling machine is our company’s star product, we can customize the equipment capacity from 300-20000 bottles per hour to meet the various client’s actual requests. The excellent running performance and reliable after-sales service are satisfied by every client.